Automating Dimension Comparison Between Customer Drawings and Recreated CAD Files

Comparing customer-supplied drawings with internally recreated CAD drawings, reducing manual verification from hours to minutes.

Objectives and Metrics for Success

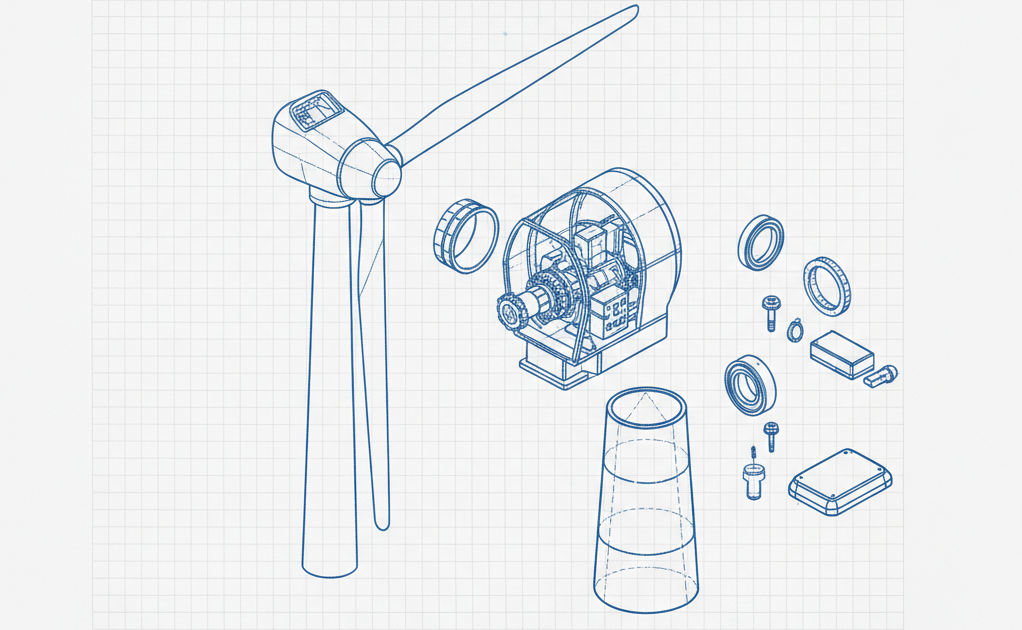

The client manufactures wind turbine components. They receive customer-supplied drawings and recreate them as CAD files to enable modern manufacturing workflows. Before releasing a recreated drawing to manufacturing, quality engineers must verify that every dimension matches the original. Each drawing contains 50 to 150 dimensions. Manual verification took 2 to 3 hours per drawing pair and still missed 5 to 10 percent of dimensions. The goal was to automate this comparison while providing clear reporting on what matched, what differed, and what was missing.

The Problem

Recreating customer drawings as CAD files is standard practice for modern manufacturing. But verifying that the recreated drawing matches the original creates a bottleneck. Quality engineers compare dimensions one by one, a slow process that delays drawing release and still misses critical measurements.

Manual Verification Bottleneck

Quality engineers spend 2 to 3 hours per drawing pair manually cross-checking 50 to 150 dimensions. The process is tedious and error-prone, creating a bottleneck in the drawing release cycle.

Missed Dimensions

Manual comparison overlooks 5 to 10 percent of dimensions, especially in complex drawings with dense annotations. When critical measurements are missing from recreated drawings, manufacturing errors follow.

No Structured Tracking

Discrepancies are identified ad hoc with no clear categorization. Missing dimensions, value mismatches, and tolerance changes are all treated the same, slowing root cause analysis.

Delayed Release Cycles

Manual verification adds 1 to 2 days per drawing set. Across 20 to 30 recreated drawings, delays compound into 4 to 6 weeks, directly impacting manufacturing schedules.

The Approach / Methodology

The implementation combined dual extraction with intelligent matching to automate verification while handling the variations that occur when drawings are recreated. Each phase extended platform capabilities while maintaining the accuracy required for quality assurance.

Dual Extraction Pipeline

Implementation of a single extraction workflow that processes both customer-supplied drawings and internally recreated CAD drawings, enabling direct comparison from different sources.

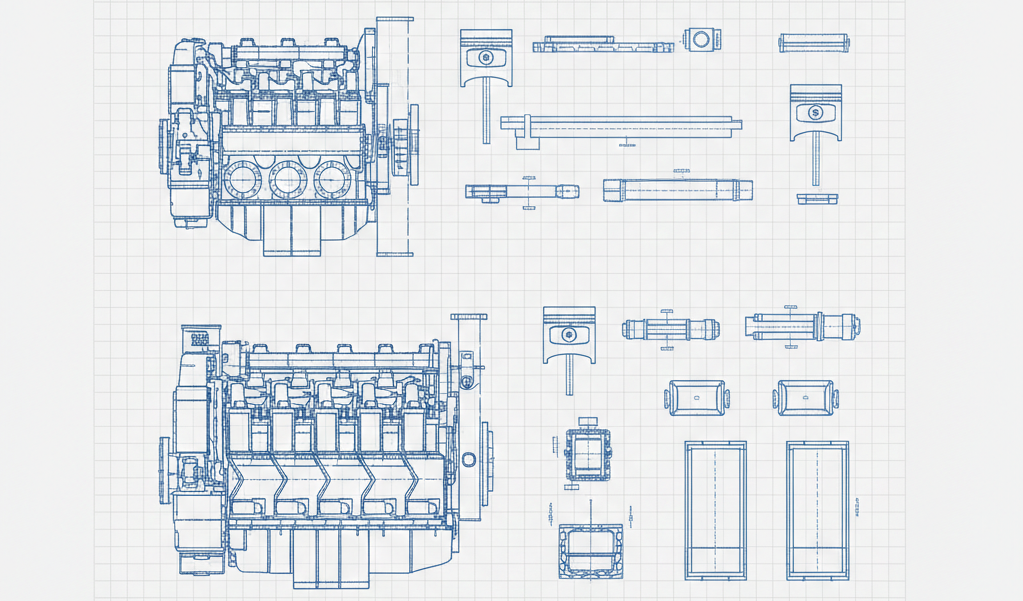

Multi-Format Dimension Detection

Deployment of computer vision detecting dimension lines, arrows, and leader lines across ASME Y14.5, ISO, and company-specific standards. Technical OCR recognizes numeric values, units, and tolerances in varied formats.

GD&T Recognition and Spatial Indexing

Development of GD&T extraction identifying geometric tolerances with datum references. Spatial indexing captures X-Y coordinates for every dimension to enable position-based matching.

Fuzzy Matching Engine

Implementation of matching algorithm that pairs corresponding dimensions across drawings despite positional shifts, rotations, and annotation differences introduced during recreation.

Visual Reporting Interface

Development of side-by-side reports with color-coded overlays showing green for matches, yellow for mismatches, and red for missing dimensions. Interactive tables enable fast review and sign-off.

Solution Implementation

Adeos processes both customer drawings and recreated CAD drawings through the same extraction workflow. The system detects dimensions, extracts values, and compares the two datasets automatically. Discrepancies are categorized and presented in visual reports that enable fast review.

Dual Extraction for Direct Comparison

The same extraction workflow processes both customer-supplied drawings and internally recreated CAD drawings. This creates directly comparable datasets that reveal discrepancies without reviewer bias.

Fuzzy Matching for Recreation Variations

Recreated CAD drawings introduce positional shifts, rotations, and annotation style differences even when dimensions are correct. The matching engine accounts for these variations while identifying actual value and tolerance discrepancies.

Multi-Level Discrepancy Classification

The system categorizes comparison outcomes into exact matches, value mismatches, tolerance mismatches, missing dimensions, and extra dimensions. This enables engineers to address critical issues first.

Visual Reporting with Color-Coded Overlays

Side-by-side annotated reports show green for matches, yellow for mismatches, and red for missing dimensions. Engineers can navigate between visual overlays and tabular summaries for efficient review.

Results

The deployment automated dimensional verification while maintaining the accuracy required for manufacturing release. Quality engineers now review automated comparisons instead of performing manual cross-checks.

Manual verification reduced from 2 to 3 hours per drawing pair to 10 to 15 minutes

95%+ comparison accuracy regardless of drawing complexity

99% detection rate for missing dimensions

Clear categorization into matches, mismatches, and missing dimensions enabling targeted fixes

Visual reports with color-coded overlays accelerating review and approval

Drawing release cycle reduced by 1 to 2 days per drawing set

Key Learnings / Insights

This deployment demonstrated principles that apply broadly to drawing verification: the importance of extracting from both sources, handling recreation-induced variations, and providing clear visual reporting for fast review.

Dual Extraction Removes Reviewer Bias

Applying the same extraction workflow to both drawings ensures unbiased comparison. Extracting from one source and manually checking the other introduces inconsistency. Dual extraction creates comparable datasets that reveal discrepancies clearly.

Fuzzy Matching Handles Recreation Variations

Recreated CAD drawings shift positions, rotate views, and change annotation styles even when dimensions are correct. Exact position matching fails on valid recreations. Fuzzy matching identifies actual discrepancies while accounting for these variations.

Categorization Enables Targeted Fixes

Ad hoc discrepancy identification slows root cause analysis. Structured categorization distinguishing missing dimensions from value mismatches enables engineers to address critical issues before annotation differences.

Visual Reporting Accelerates Review

Tabular lists require engineers to locate dimensions on drawings manually. Color-coded overlays enable immediate identification of problem areas. Interactive navigation between visual and tabular views combines overview clarity with detailed analysis.

“Verifying dimensional accuracy took 2 to 3 hours per drawing. Adeos extracts from both the customer drawing and our recreated CAD drawing, then compares them automatically. What took hours now takes 10 to 15 minutes. We were even able to get reports of common patterns where errors happened.”

Conclusion

The drawing comparison deployment demonstrates how Adeos automates dimensional verification between customer-supplied drawings and internally recreated CAD drawings. By applying dual extraction with intelligent matching and providing clear visual reporting, the platform reduces manual verification from hours to minutes while catching missing dimensions that would cause manufacturing errors.

Experience Automated Drawing Comparison Today

Ready to see how Adeos can streamline your engineering document workflows?

Browse More Success Stories

Automating Dimension Extraction and Welding Calculations for Power Boiler Manufacturing

Replacing manual drawing review across departments with automated extraction and formula-driven calculations for supercritical boiler fabrication.

Automating Filtered Dimension Extraction for Lift Manufacturing

Extracting dimensions with abbreviations filtering and confidence-scored outputs from engineering drawings at scale.

Adeos Marine: Automating BOM Extraction Across a Global Fleet

Transforming weeks of manual data entry into a 48-hour automated workflow for bill of materials extraction from legacy marine manuals.