Adeos Marine: Automating BOM Extraction Across a Global Fleet

Transforming weeks of manual data entry into a 48-hour automated workflow for bill of materials extraction from legacy marine manuals.

Objectives and Metrics for Success

The client managed a fleet of over 700 vessels, each with technical manuals containing critical bill of materials data. Their goal was to eliminate manual data entry from the BOM extraction process while maintaining the accuracy required for downstream procurement and maintenance systems. Success required three outcomes: reduce processing time from weeks per manual to days, achieve extraction accuracy above 90% without requiring page-by-page human review, and produce structured output that could integrate directly with their existing Master Data Management system without reformatting.

The Problem

Manual Data Entry at Scale

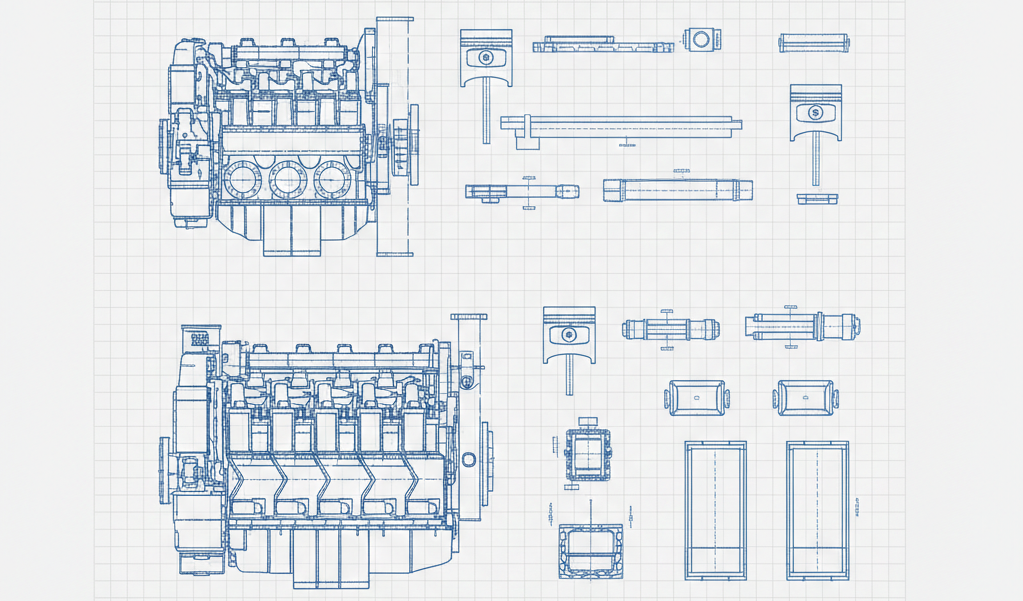

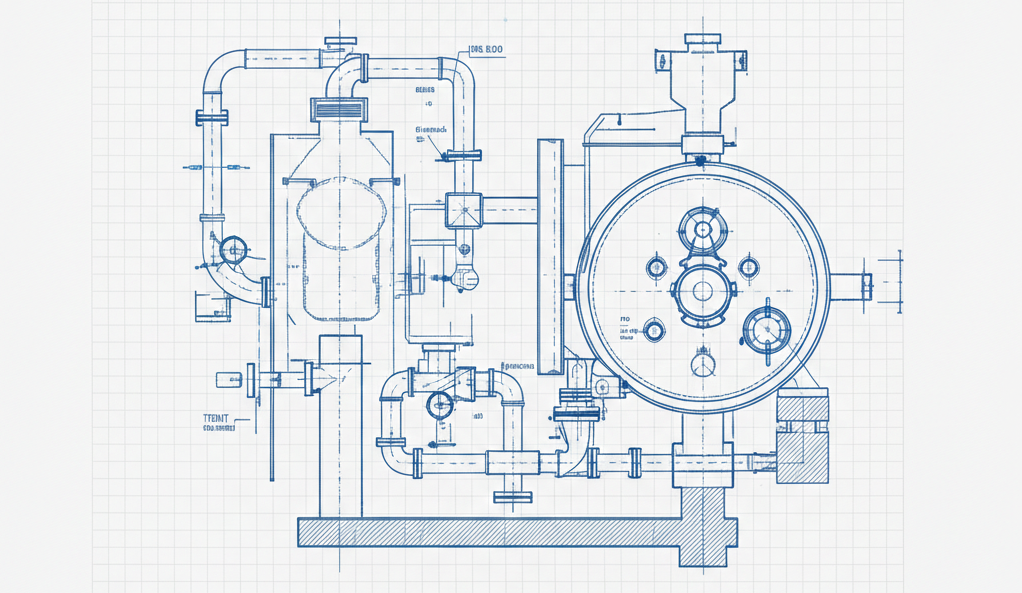

Each technical manual contained 100 to 1,000 pages of component tables and part specifications. Extracting BOM data manually required hours per page, stretching to weeks for a single manual.

Inconsistent Multilingual Documents

The archive contained manuals from shipyards across Japan, Korea, China, and Russia. Each followed different formatting conventions with variable scan quality and nested multi-page assemblies.

Downstream Data Dependencies

Extracted BOM data fed directly into procurement, inventory management, and maintenance systems. Errors in extraction created cascading problems across fleet operations.

The Road to Implementation

We implemented an end-to-end BOM extraction workflow combining automated layout detection with human-in-the-loop verification to process multilingual marine manuals at scale.

Document Assessment

Analysis of manual samples from each shipyard origin to identify table formats, extraction challenges, and quality thresholds.

Layout Detection Calibration

Training Adeos vision models to recognize BOM table structures across the full range of formatting conventions in the archive.

Annotation Workflow Deployment

Implementation of the human-in-the-loop interface for operators to review and correct automated annotations before extraction.

MDM Integration

Configuration of Excel output formatting to match the client's Master Data Management system schema for direct import.

Custom Architecture Built

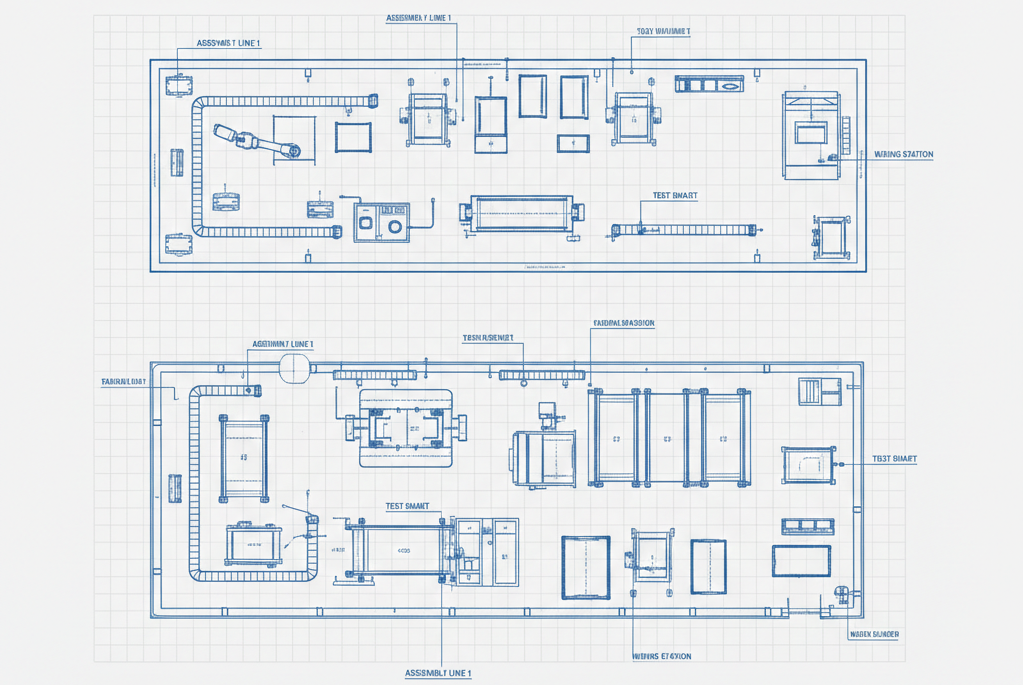

Unified Processing Interface

Adeos provided a single interface for the entire workflow: manual upload, auto-detected layouts, annotation correction, automated extraction, and confidence-based quality control.

Intelligent Layout Detection

The platform automatically identifies table boundaries, column headers, and row structures across inconsistent document formats, flagging low-confidence pages for manual review.

Confidence-Based Quality Control

Each extracted record receives a confidence score. Records below threshold are flagged for human verification, maintaining accuracy without requiring review of every page.

The Outcome

Processing time reduced from weeks to under 48 hours per manual

Over 15,000 pages processed across 100+ technical manuals

Extraction accuracy exceeding 94% with human-in-the-loop verification

Direct integration with existing Master Data Management system

System remains in active production use across ongoing digitization efforts

Key Learnings

Multilingual Documents Require Flexible Detection

The archive contained manuals from four shipyard traditions with distinct table conventions. Layout detection trained on document variety proved more robust than rule-based extraction.

Human-in-the-Loop is a Feature

Corrections made during QC feed back into the system. Operators reviewing flagged pages caught edge cases that no model would handle reliably, improving downstream accuracy without slowing throughput.

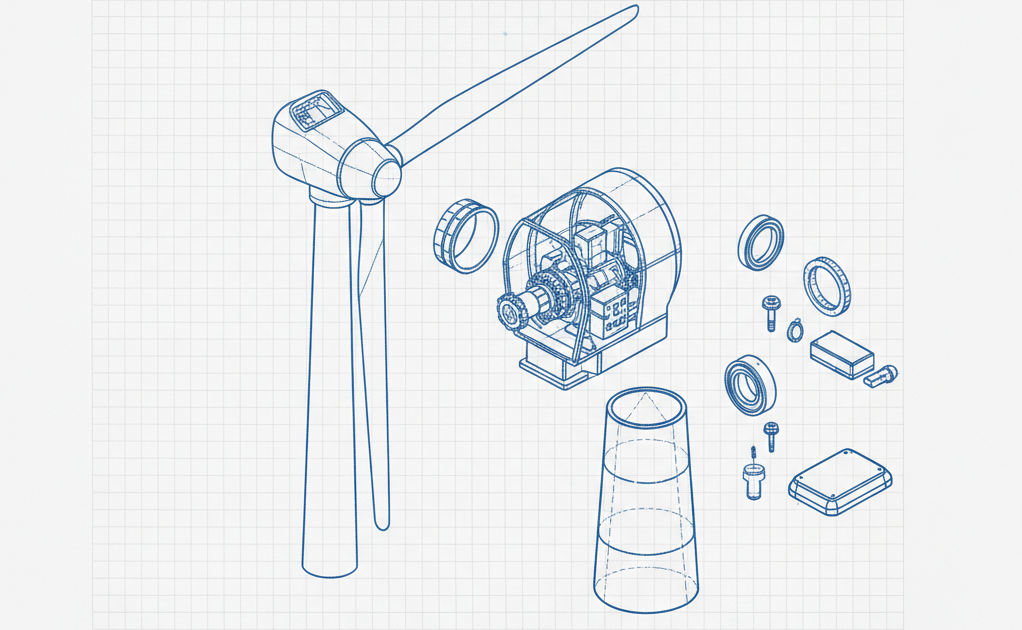

Level 3 Autonomy Fits Document Intelligence

The system operates autonomously within defined boundaries, escalating to human oversight when confidence drops. Most pages process cleanly, but some require judgment only a human can provide.

“We had years of technical manuals sitting in archives, effectively unusable for any systematic analysis. Adeos gave us a way to extract that data without building a massive data entry team. The system handles the volume, and our people focus on the exceptions.”

Conclusion

The BOM extraction deployment demonstrates how Adeos handles document intelligence at scale without sacrificing accuracy. By combining automated detection with structured human oversight, the platform processes inconsistent, multilingual source documents while maintaining the data quality required for downstream business systems. The system continues to operate in production, processing new manuals as they enter the fleet archive.

Experience Automated Document Extraction Today

Ready to see how Adeos can streamline your document processing workflows?

Browse More Success Stories

Automating Dimension Extraction and Welding Calculations for Power Boiler Manufacturing

Replacing manual drawing review across departments with automated extraction and formula-driven calculations for supercritical boiler fabrication.

Automating Filtered Dimension Extraction for Lift Manufacturing

Extracting dimensions with abbreviations filtering and confidence-scored outputs from engineering drawings at scale.

Automating Dimension Comparison Between Customer Drawings and Recreated CAD Files

Comparing customer-supplied drawings with internally recreated CAD drawings, reducing manual verification from hours to minutes.