Automating Filtered Dimension Extraction for Lift Manufacturing

Extracting dimensions with abbreviations filtering and confidence-scored outputs from engineering drawings at scale.

Objectives and Metrics for Success

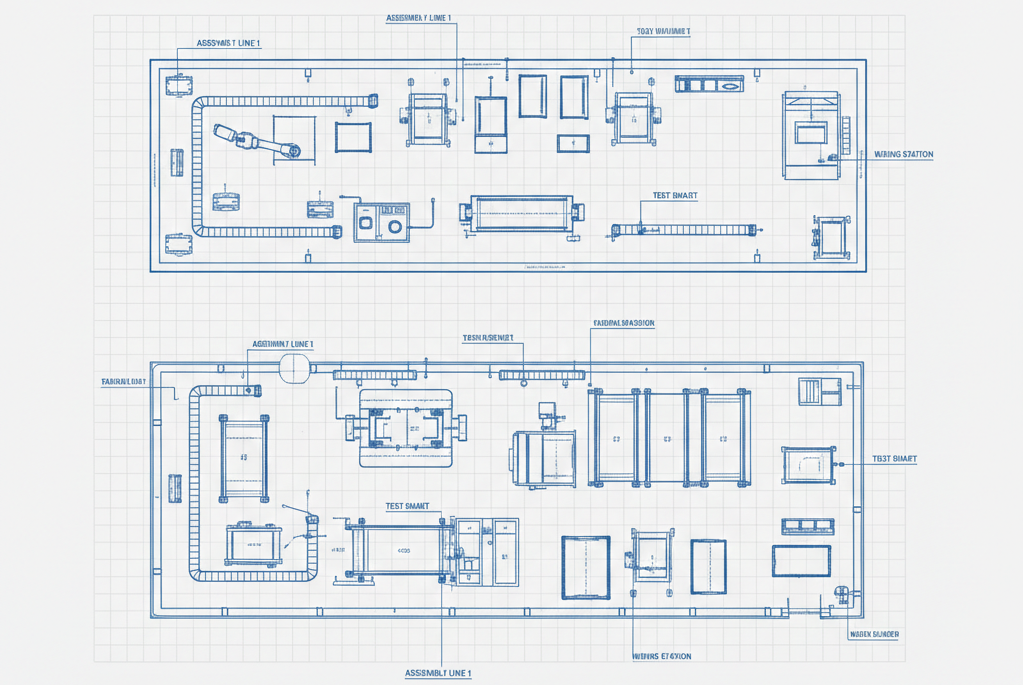

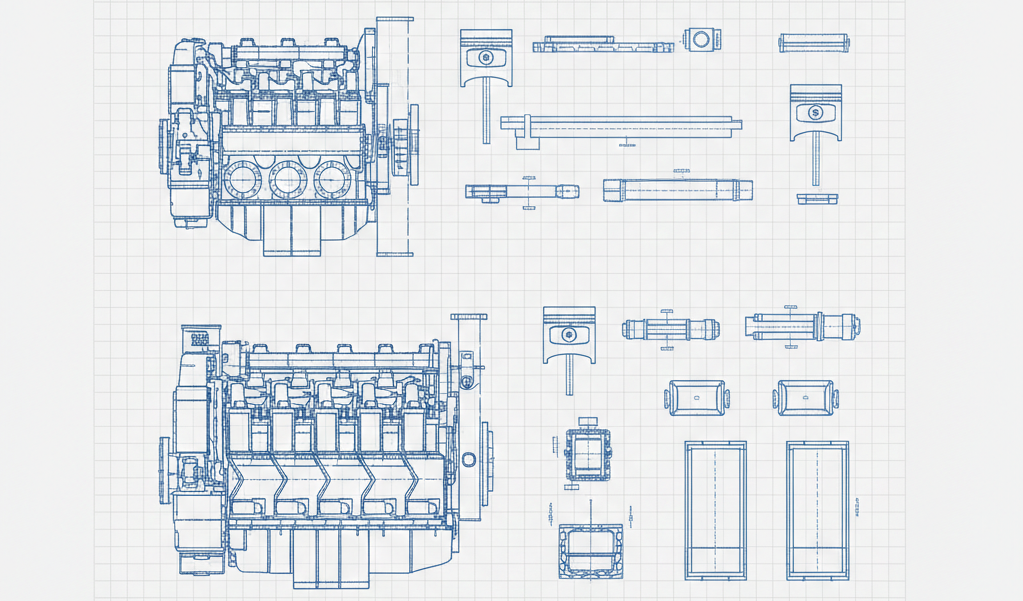

The client manufactures lifts and elevators, processing 50 to 200 layout drawings daily from both internal AutoCAD systems and external client submissions. Their goal was to automate dimension extraction filtered by abbreviation suffix. Success required four outcomes: extract dimensions matching target abbreviations (WW for shaft width, WD for depth, SS for size, HT for height) from both digital and scanned PDFs, correlate dimensions with associated tabular data, deliver structured Excel output ready for ERP integration, and provide confidence scores enabling risk-based quality control.

The Problem

Processing 50 to 200 layout drawings daily required engineers to manually identify dimensions by abbreviation suffix, interpret varying conventions across document formats, and reformat data for downstream systems. The workflow could not scale without proportional headcount increases.

Mixed Document Formats

Engineering teams received both digital AutoCAD-generated PDFs and scanned client PDFs. Each format required different handling, and inconsistent quality affected extraction reliability.

Manual Dimension Identification

Identifying dimensions with correct abbreviation suffixes demanded significant interpretation time. Engineers located target dimensions, interpreted abbreviation conventions, and extracted related tabular data manually.

Scale Constraints

Manual workflows could not handle peak volumes of 200 drawings per day without adding headcount. Processing capacity was constrained by available engineering hours.

Integration Friction

Extracted data needed structuring for ERP and planning workflows. Manual transcription into required formats introduced errors and delays in downstream processes.

The Approach / Methodology

Implementation moved from document analysis through pipeline configuration to production deployment. Each phase validated extraction accuracy before expanding to full processing volumes.

Document Analysis

Analysis of sample drawings across formats, identifying abbreviation conventions, layout patterns, and quality variations to inform extraction configuration.

Pipeline Configuration

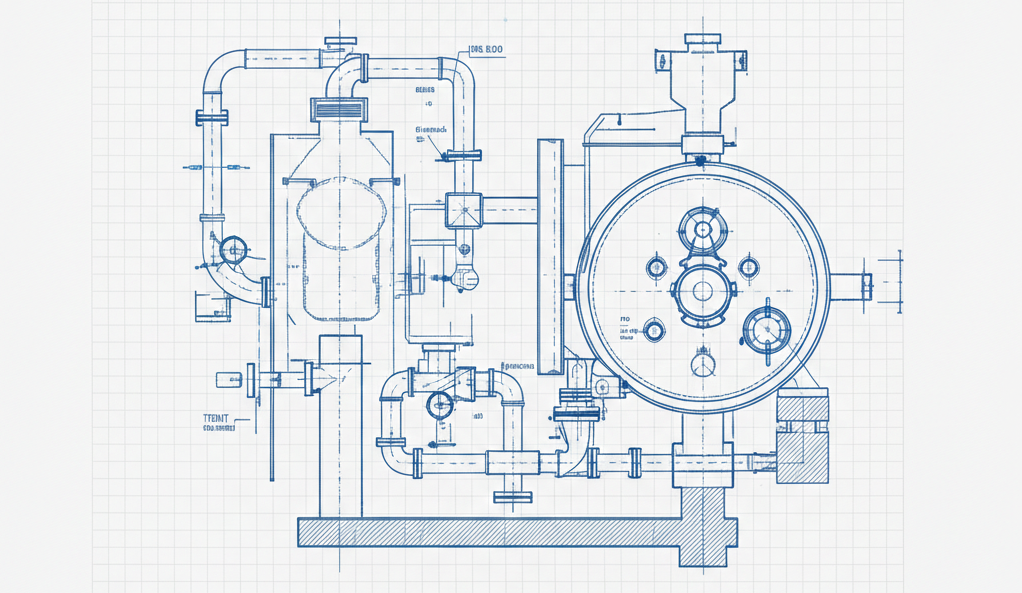

Configuration of on-premise VLM and OCR pipeline for lift manufacturing drawing characteristics, including dimension formats and table structures.

Output Standardization

Design of two-sheet Excel templates (Drawing Dimensions and Tabular Data) matching downstream ERP and planning system requirements.

API Integration

Integration of real-time extraction API with existing engineering systems, enabling automated document submission and result retrieval.

Solution Implementation

Adeos deployed an on-premise pipeline combining vision language models with OCR. Drawings are processed through abbreviation-based filtering, table correlation, and confidence scoring. The result is structured Excel output from a single extraction pass, ready for ERP integration.

Hybrid Document Processing

On-premise VLM combined with OCR handles both digital AutoCAD PDFs and scanned client PDFs in a single pipeline, maintaining accuracy across document quality variations.

Intelligent Abbreviation Filtering

The system extracts only dimensions matching target suffixes (WW, WD, SS, HT), eliminating irrelevant data automatically and reducing downstream processing.

Table Correlation

Associated tabular data is extracted and linked to corresponding dimensions in one pass, preserving relationships between measurements and specifications.

Confidence-Scored API Output

Real-time API returns confidence scores with each extraction, enabling QC teams to focus review on lower-confidence results rather than checking everything uniformly.

Results

The deployment eliminated manual dimension interpretation as a bottleneck. Processing capacity scaled independently of engineering headcount, with confidence scoring enabling efficient quality control.

80-90% reduction in manual effort per drawing

Processing capacity scaled to 200 drawings per day at peak

Consistent two-sheet Excel output for every extraction

Both digital and scanned PDFs processed in single workflow

QC efficiency improved through confidence-based review prioritization

Direct integration with ERP and planning systems achieved

Key Learnings / Insights

This deployment reinforced principles for manufacturing document intelligence: hybrid processing for format variability, domain-specific configuration for relevance, and output design for adoption.

Hybrid Processing Handles Format Variability

Combining VLM and OCR in one pipeline addresses the full range of document quality without requiring separate workflows for digital and scanned sources.

Domain Configuration Beats Generic Extraction

Industry-specific abbreviation conventions (WW, WD, SS, HT) require explicit setup. Generic extraction returns too much irrelevant data to be useful.

Confidence Scoring Enables Scalable QC

Providing confidence scores with each extraction allows quality assurance to scale with volume through risk-based review rather than uniform checking.

Output Format Drives Adoption

Excel templates matching existing ERP requirements eliminated integration friction. The value of extraction is realized only when data flows into downstream workflows.

“Our engineers were spending hours on each drawing set, finding the right dimensions and typing them into spreadsheets. Now the system extracts exactly what we need, filtered by abbreviation, with confidence scores that tell us where to focus review. We process more drawings with fewer errors.”

Conclusion

The dimension extraction deployment demonstrates how Adeos handles high-volume manufacturing workflows with mixed document formats. By filtering extractions to relevant abbreviations and scoring confidence, the platform replaced manual interpretation with scalable, reliable automation. Engineering teams now focus on exceptions rather than routine extraction.

Automate Your Dimension Extraction Workflows

Ready to see how Adeos can streamline your engineering document processing?

Browse More Success Stories

Automating Dimension Extraction and Welding Calculations for Power Boiler Manufacturing

Replacing manual drawing review across departments with automated extraction and formula-driven calculations for supercritical boiler fabrication.

Automating Dimension Comparison Between Customer Drawings and Recreated CAD Files

Comparing customer-supplied drawings with internally recreated CAD drawings, reducing manual verification from hours to minutes.

Adeos Marine: Automating BOM Extraction Across a Global Fleet

Transforming weeks of manual data entry into a 48-hour automated workflow for bill of materials extraction from legacy marine manuals.