Automating Dimension Extraction and Welding Calculations for Power Boiler Manufacturing

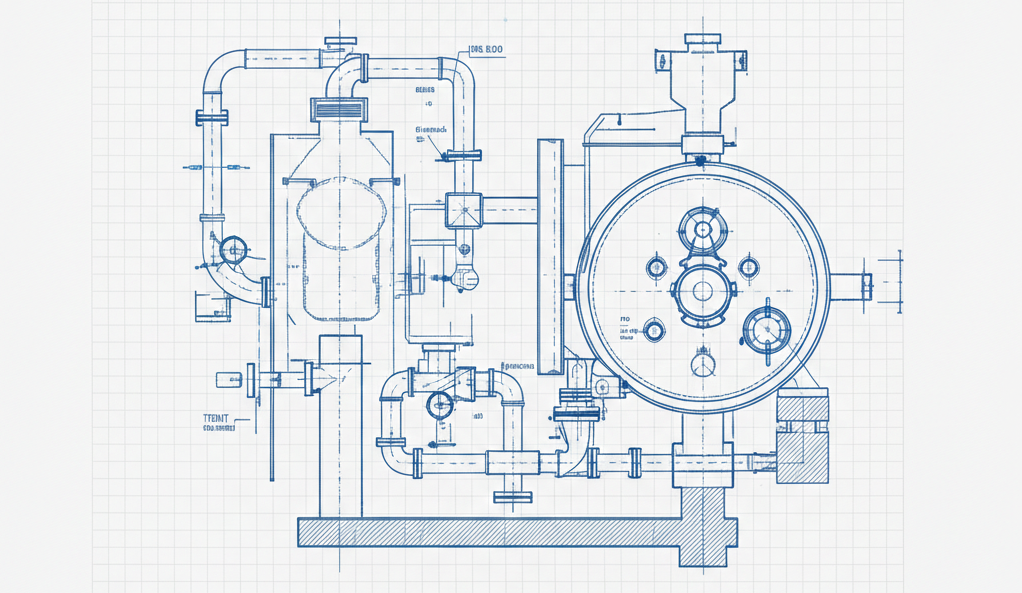

Replacing manual drawing review across departments with automated extraction and formula-driven calculations for supercritical boiler fabrication.

Objectives and Metrics for Success

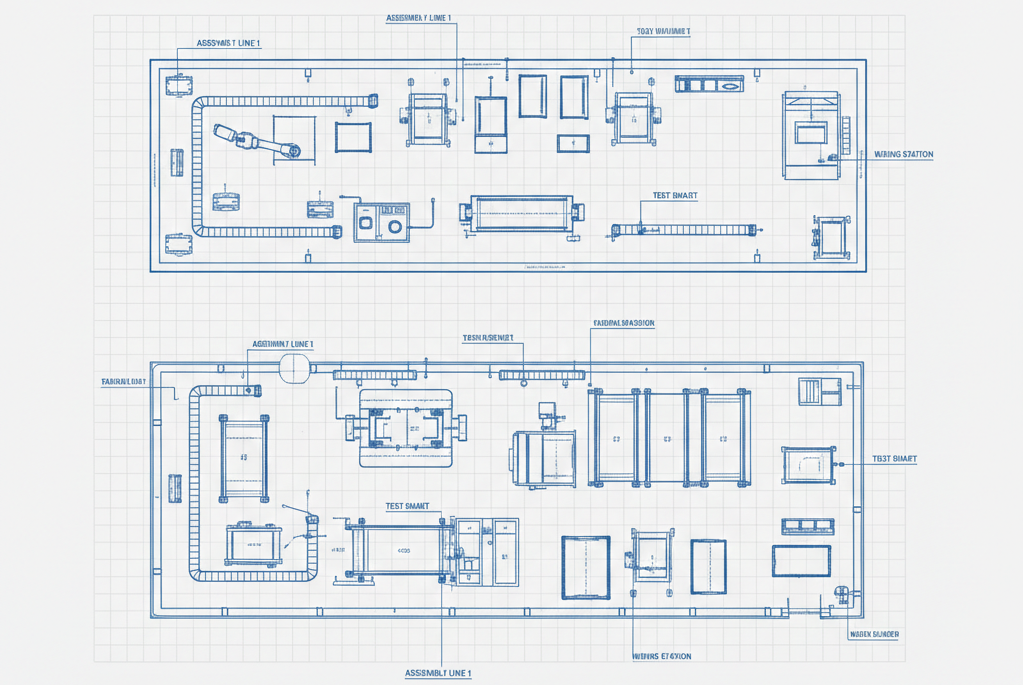

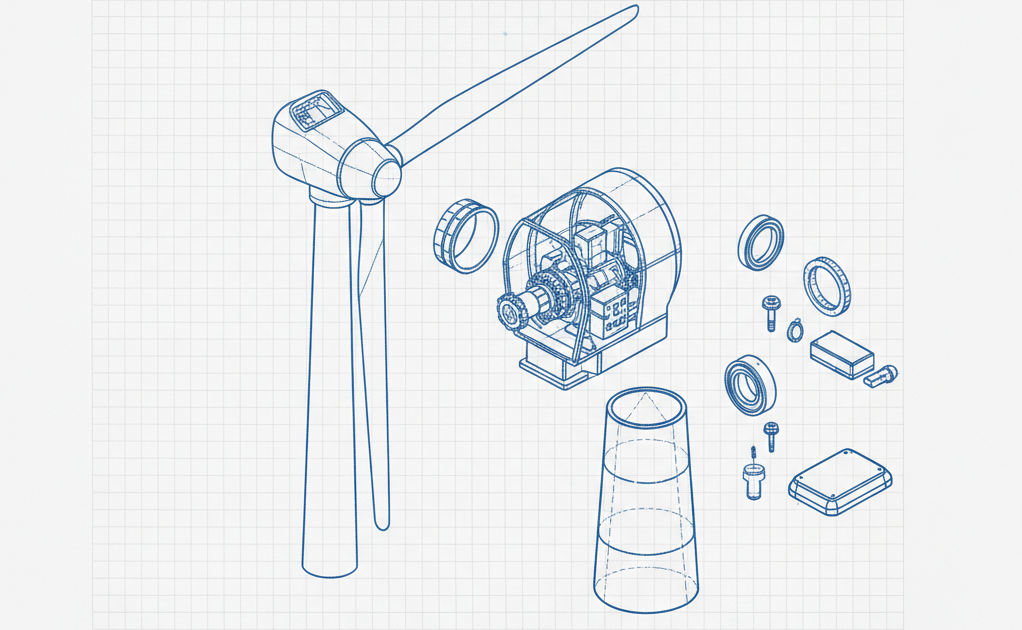

The client designs, manufactures, and services high-efficiency supercritical boilers and pulverizers for power plants, specializing in large-scale units of 500 MW and above using advanced low-NOx technologies. Each project involves 50 to 100 weld detail drawings that must be reviewed by Design & Engineering, Manufacturing, and Procurement teams. Their goal was to eliminate redundant manual extraction across departments. Success required three outcomes: extract dimensions once and distribute to all departments in their required format, apply the client's existing formula library automatically to calculate material and consumable requirements, and feed outputs directly into production planning and procurement systems without manual reformatting.

The Problem

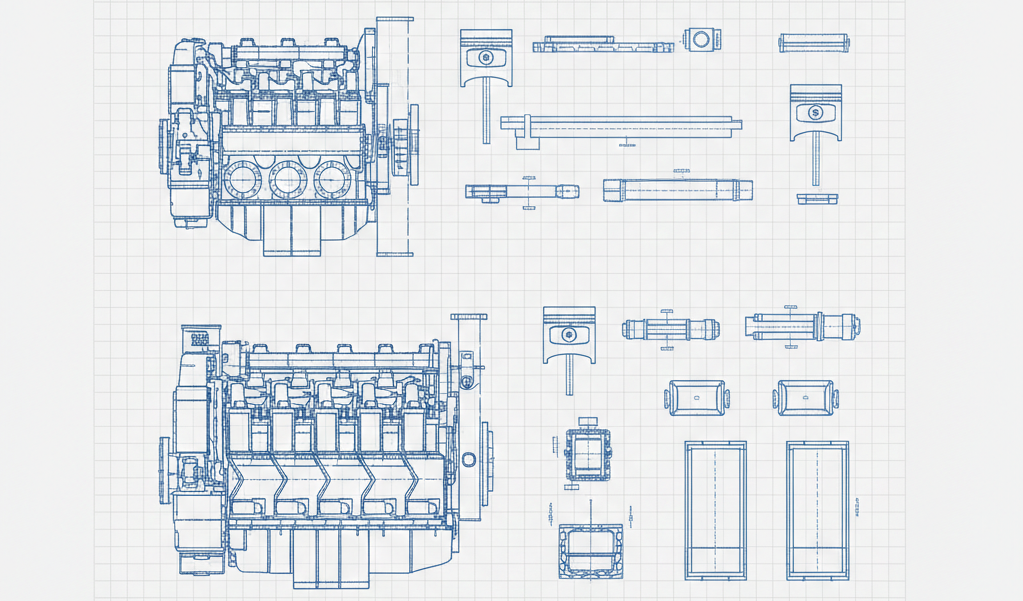

A supercritical boiler project generates 50 to 100 weld detail drawings. Each drawing contains dimensions that three departments need for different purposes. Without a shared extraction workflow, every department reviewed every drawing independently, duplicating effort and introducing inconsistencies that rippled through production planning.

Redundant Manual Extraction

Each of the departments independently reviewed hundreds of drawings per project, extracting the dimensions relevant to their function. The same drawing was handled multiple times with no shared workflow.

Non-Native Drawing Formats

Vendor drawings arrived as PNGs or PDFs rather than native CAD files. Dimensions could not be extracted programmatically using conventional CAD tools, forcing manual measurement and transcription.

Manual Calculation Errors

The client maintained formulas for welding consumption and material requirements, but these were applied manually in spreadsheets. Errors in dimension transcription cascaded into incorrect calculations, affecting production schedules and procurement orders.

The Approach / Methodology

The implementation moved from requirements gathering through formula integration to production deployment. Each phase built on the previous, ensuring that department-specific needs were captured before extraction workflows were configured.

Department Requirements Mapping

Documentation of dimension requirements for each department, identifying overlaps and unique needs across Design & Engineering, Manufacturing, and Procurement.

Formula Library Integration

Configuration of the client's existing calculation formulas within Adeos, mapping each formula to its required dimension inputs.

Extraction Workflow Deployment

Implementation of dimension detection with bounding boxes, extraction to structured lists, and human review for formula-dimension mapping.

System Integration

Configuration of outputs for direct import into production planning and procurement systems.

Solution Implementation

Adeos provided a single extraction interface that serves all three departments. Vendor drawings in PNG or PDF format are processed through dimension detection, human-verified formula mapping, and automated calculation. The result is department-specific outputs generated from one extraction pass.

Unified Multi-Department Extraction

A single extraction workflow serves all three departments. Dimensions are extracted once and distributed in department-specific formats, eliminating redundant manual review.

Formula Library Integration

The client's existing calculation formulas are maintained within Adeos. Welding consumption, material weight, and other calculations are applied automatically once dimensions are mapped.

Human-in-the-Loop Formula Selection

Operators review and confirm which dimensions feed into which calculations. This step ensures accuracy for complex drawings where automated mapping might be ambiguous.

Results

The pilot validated the core hypothesis: extracting once for multiple departments eliminates redundant work without sacrificing accuracy. Processing time, error rates, and system integration all improved as expected.

Hundreds of weld detail drawings processed per project through single workflow

Three departments served from unified extraction, eliminating redundant review

Manual extraction time reduced from days to hours per drawing set

Calculation errors reduced through automated formula application

Outputs integrated directly with production planning and procurement systems

Pilot ongoing with expansion planned

Key Learnings / Insights

This deployment reinforced principles that apply broadly to manufacturing document intelligence: where to place human review, how to preserve client IP, and why multi-department workflows deliver compounding returns.

Multi-Department Workflows Multiply Value

Extracting dimensions once for three departments delivers more value than automating any single department. The ROI compounds when redundant manual work is eliminated across functions.

Formula Libraries Are Client IP Worth Preserving

The client had developed calculation formulas over years of operation. Adeos applies these formulas rather than replacing them, preserving institutional knowledge while automating execution.

Non-Native Formats Are the Real Challenge

Vendor drawings in PNG or PDF format cannot be processed by conventional CAD tools. Vision-based extraction handles these formats where programmatic approaches fail.

Human Review Belongs at Decision Points

Automated extraction handles volume. Human review at the formula selection step handles ambiguity. This division of labor maintains accuracy without sacrificing speed.

“We had three teams looking at the same drawings and typing the same numbers into different spreadsheets. Adeos gave us one extraction that feeds everyone. The formulas we have been using for years now run automatically. Our production planning starts with clean data instead of chasing errors.”

Conclusion

The dimension extraction deployment demonstrates how Adeos serves manufacturing workflows that span multiple departments. By extracting once and distributing to many, the platform eliminates redundant manual work while preserving the client's existing calculation methods. The pilot continues with plans to expand across additional project types as the workflow proves out.

Experience Automated Dimension Extraction Today

Ready to see how Adeos can streamline your engineering document workflows?

Browse More Success Stories

Automating Filtered Dimension Extraction for Lift Manufacturing

Extracting dimensions with abbreviations filtering and confidence-scored outputs from engineering drawings at scale.

Automating Dimension Comparison Between Customer Drawings and Recreated CAD Files

Comparing customer-supplied drawings with internally recreated CAD drawings, reducing manual verification from hours to minutes.

Adeos Marine: Automating BOM Extraction Across a Global Fleet

Transforming weeks of manual data entry into a 48-hour automated workflow for bill of materials extraction from legacy marine manuals.